Inertial Profilers

Highly Modular Sensors. Superior Software. Guaranteed to comply with smoothness requirements

SSI’s Inertial Profilers Have More Features, Are Easier To Operate, and Perform Better Than Other Systems. SSI Guarantees Compliance With Industry Specifications For Ride Quality Testing.

Configurations

SSI offers a variety of unique configurations of inertial profiling devices. Choose between five models:

- CS9100 Mid-Mount Inertial Profiler, most popular with agencies and contractors

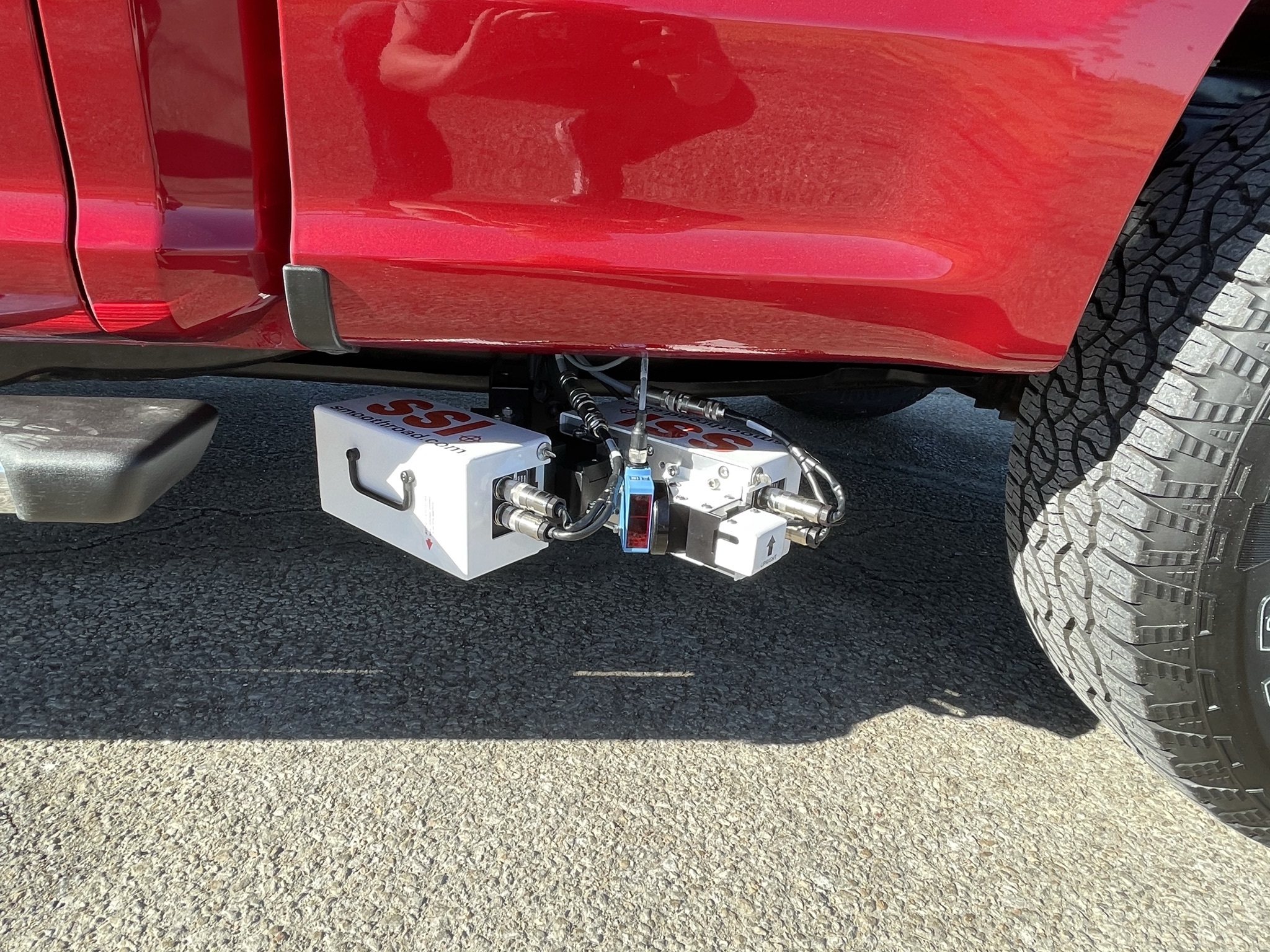

- CS9300 Portable Bumper Mount Inertial Profiler

- CS8700 Lightweight Profiler

- CS9400 Single Laser Simple Profiler

- Custom trailer-mounted CS9200 Multiple Purpose Profiler.

For use under typical QA/QC applications, SSI offers single, dual or three laser inertial profiling systems. SSI’s single laser profilers can output dual wheel path reports, with SSI’s patented alignment of separate data collections into a single report (with the results summarized and averaged). The dual and three track systems collect multiple tracks of surface data simultaneously. All of SSI’s inertial profilers are high capacity, durable tools that can be used throughout all project phases – from assessment of original surface ride quality prior to bidding – to tracking surface conditions during construction – to monitoring smoothness throughout the life cycle of mature pavements.

Design

All of the inertial profilers offered by SSI feature our custom built hardware and electronics paired with high accuracy lasers or industrial grade sensors. All hardware is professionally engineered for use on construction sites. SSI’s electronics are designed by PhD engineers and built by ISO-9001 certified manufacturers. Our software programs evolve from a structured engineering process that includes end user input as an important element. With the modular design of SSI’s equipment, we provide the ability to transfer the core components and functionality from one vehicle to another quickly and easily.

Each SSI hardware platform uses the same set of core data collection components. The modular design allows for rapid response support, as all key components are field replaceable, “plug-and-play,” and express shippable.

Proven Repeatability & Accuracy

SSI’s performance has been proven by worldwide compliance with agency specifications and test methods. SSI inertial profilers are Class I profiling devices under ASTM E950 at all collections speeds from 5 mph to over 100 mph (8-160 kph; 0-100 mph for Zero-Speed systems). SSI’s systems not only comply with, but are guaranteed to meet or exceed applicable specifications and certification requirements worldwide. This includes US Federal and State DOT, Ministries of Transportation, ASTM and AASHTO (M328, R054, R056-R057) and World Bank standards.

Unmatched Precision

SSI’s inertial profiling systems can pinpoint localized roughness (bumps and dips) with unrivaled precision. Using these accurate profiles operators can use SSI software to navigate and pin-point localized roughness. The same process can be used on grinders and mills to adjust their machines according changes in surface profiler. Contact SSI for more details on these innovative solutions.

Software

SSI Profiler is an all-in-one collection, viewing, editing, reporting and exporting software based off of a Windows operating system. The calibration and data collection routines are simple and computer instructed. The SSI Profiler data analysis program has evolved since 1995 through development based on end-user input and field experience.

Profile data is saved to SSI’s proprietary format which compresses the sensor data into a size that is easily transferred. The data can be exported into multiple formats including PPF and ERD (fully compatible with ProVal), PDF, Excel, and GIS shapefiles.

SSI’s Data Validation Engine software allows for fast comparison of data from repeat profile collections and sensor troubleshooting. Analysis options include profile repeatability, accuracy, and cross-correlation, as well as comparisons of elevations, raw sensor data, and GPS content.

SSI software is licensed and available on multiple operator computers. Updates are automatically available with access to the internet.

Device Rating

SSI inertial profilers conform with the following standards or test methods. All inertial profilers are guaranteed to comply with DOT standards and the following:

- ASTM E950

- AASHTO m328

- AASHTO r54

- AASHTO r56

- AASHTO r57

- TxDOT 1001-S

- Real Time Diagnostics

Profiling system health monitored by real-time diagnostics to verify integrity of main profiling system electronics, all sensors, and data communication interface. Visual and audible feedback. - Software Updates

Self-executing program updates overwrite prior versions. Supplied by internet download. - In-Field Component Replacement

All collection system components portable, modular for in-field replacement. - Warranty

Industry standard one year warranty on all profiling system components and accessories. Extended warranty options available. - Customer Support Representatives

Customer assistance available worldwide by telephonic, e-mail and on-site assistance (24×7 support available as requested or needed).

Wide Footprint Lasers

Surfaces with high voids or texture are recommended or required to be collected with a wide-footprint laser. These line lasers were developed to minimize the artificial impact of single point lasers on concrete or other pavement finishes with significant texture attributes, such as longitudinal tines or grooves from diamond grinding. The line laser collects an average height measurements over a 4 inch (100 mm) or larger lateral line, as compared to spot lasers that sample using a beam no wider than about 0.25” (6.35mm).

- Dot laser sensor sampling frequency: 32KHz (32,000 samples/second)

- Line laser sensor sampling frequency: 5KHz (5,000 samples/second)

- Laser vertical measurement resolution is between 0.015 and 0.56-mm, depending on laser type.

- The lasers have a 3B/lllb classification under the standards relating to laser products specified in IEC 60825-1 and U.S. FDA CFR Title 21 Part 1040 and Laser Notice No. 50, dated July 26, 2001

- Class 3B/lllb components are UNSAFE for eye exposure. Usually only ocular protection would be required. Diffuse reflections are safe if viewed for less than 10 seconds. WARNING: DO NOT look directly into the laser beam. It is recommended that wearing laser safety goggles (for Class 3B/IIIb lasers) be worn if a user of the profiling system is in the vicinity of the profiling system hardware when the lasers are operational.

Data Quality Specifications

- Data Sampling

1-inch at highway speeds (user can adjust sampling for specialized collections) - Optical encoder Distance Measurement Instrument (DMI)

Accuracy of 0.1% - Vertical Acceleration

Host vehicle suspension dynamic measured with aerospace grade accelerometer sensors (rated for up to +/- 5g or 10g; resolution to 0.0001g). - Profile Feature and Wavelength Preservation

Proven ability to measure and preserve fine surface features more accurately than any competing system. Standard profile wavelength preservation from ~0.25 feet (76.2 mm) in excess of ~8,000 feet (2,438 meters). With optional survey subsystem added to SSI profiling system, long wavelengths preservation is thousands of feet (theoretically infinite). - Repeatability & Accuracy

Guaranteed to meet or exceed industry standards and specifications (including ASTM E950, AASHTO M328, R056, and DOT including Texas 1001-S).

Hardware Specifications

- Operator Interface Computer

Mil-Spec tested Panasonic Toughbook 20/31 ruggedized notebook computer (typical CF-31 configuration: Intel i5/i7 processor, Microsoft Windows 10 operating system, minimum 2GB RAM (expandable to 4-8 GB); minimum 160-320GB hard drive, optional DVD multi-drive, Gigabit Ethernet LAN, wireless 802.11 a/b/g/n, 13.3” SVGA display with outdoor readable touch screen; under 8 lbs; lithium-ion internal battery. Additional options and accessories available for Toughbook computer. - Profiling System Sensors

Industrial / aerospace grade sensors. System supplied with durable shielded cables with Amphenol connectors. - Mount Hardware

Professionally engineered mount hardware for attachment of inertial profiling system components onto front or rear of industry standard vehicles. Portable systems attach to standard 2 inch (5.08cm) square receiver tube and operate from host vehicle’s 12V power supply. - Flexible DMI Hardware

Hardware supplied for attachment of high resolution distance measurement interface to rear wheel of host vehicle. Dedicated lug-extenders or optional collets supplied. - Sensor Adjustment

Dove-tail hardware supplied for horizontal and vertical adjustment of laser / accelerometer sensor modules. - Adaptor Hardware

Custom hardware design and fabrication available for profiling system attachment according to customer defined requirements or specifications (front, rear, or mid-vehicle mount).

SSI Software Specifications

- SSI Profiler Software Suite

SSI internally developed software routines for profiling system calibration, data collection, data analysis and reporting. On-screen instructions for system calibration and data collection. Feature rich data analysis software. Current versions built on over 20 years of continuous development. - Profiling Programs Fully Compatible With Microsoft Windows

All software fully integrated with Microsoft Windows 10 (also Win7) - Multiple Calibration / Diagnostic Routines

Menu driven calibration routines for distance, proprietary accelerometer static calibration (in-field), bounce test (data file saved), laser height verification (0.25”/0.5”/1.00”/2.00”), rut-depth (if equipped) and cross-slope (if equipped). Internal diagnostics provide real-time monitoring of profiling system health. - User-Selectable Parameters

English or Metric units for both data acquisition and reporting; new file parameters become default (no recurring new file setup). Industry standard and user definable parameters to facilitate identification, authentication and sharing of profile data. - Real Time Display

Real time display of vehicle position and surface profile trace during data collection. - Multiple Data Collection Triggers

3 data collection triggers: (i) SSI Reverse Direction Trigger (proprietary procedure that collects exact stations without pre-marking test sections and post-testing cone removal), (ii) Electric Eye, and (iii) On-the-Fly. - Event Marking

Entry of location notes by (i) push button or electric eye, with text editing by operator after safe finish of data collection, or (ii) user configurable hot keys (assigning unique event types to particular keyboard buttons). - Urban Area Data Collection

Zero-speed option allows collections of accurate, repeatable data throughout vehicle stoppages. Collect data at any speed from 0-100 MPH. No need for lead-in or run out sections with the zero-speed option. Systems without zero-speed option have SSI “Continuous Collection” software standard, which automatically suspends the collection when speed drops below 5 MPH and resumes collection when the vehicle resumes forward travel over 5 MPH. - Pause Function with Data Retained

Pause data collection manually or with electric eye. Data from paused sections retained for reporting separately or combined with non-paused areas. - Multiple Profile Indexes

Profile data reported in multiple indexes Profile Ride Index (PRI), International Roughness Index (IRI)(by segment or continuous), Mean IRI (MRI), Half Car Ride Index (HRI), Ride Quality Index (RQI), and Ride Number (RN). - Localized Roughness

Multiple outputs of localized roughness supported. Rolling straightedge, profilograph must grind bump/dip template, Texas 1001-S localized roughness, IRI areas of localized roughness reported according to user specified IRI thresholds. Dimensions of localized roughness calculated by length of defect and peak amplitude. - Re-Writeable Data with Variable Data Analysis Parameters

Raw profile data infinitely rewritable for outputting reports and profile traces under user adjustable parameters. - Variable Filtering

Raw inertial profile data can be filtered with low pass filters (0.5 ft to 1.0 ft.) and standard high pass filters 100/200/300 ft, with scalable custom filter lengths of up to 800 feet or more for custom applications. - Multiple Trace Reporting

Patented multiple profile trace data acquisition and reporting capability. Single sensor systems report dual tracks (separately collected in either direction). - Data Conversion Sub-Routines Supplied

Export routines for conversion of profile data to industry specified formats (ERD, PPF, PRO, ASCII, CSV, Excel, Text, raw profile/ProScan, GIS and customized per request). - One Touch PDF Images

Create universally readable PDF images of profile traces and reports directly within SSI Profiler program. - Multiple Software Licenses

Data analysis software licenses provided for profiling system and desktop computer usage. - Data Encryption

Encrypted raw data files for data integrity security, raw data by repeat analysis under adjusted parameters.

Operational and Dimensions

- One Person Operation

“All-in-Cab” data collection, analysis and reporting system (profiling system data collection and analysis functions can be performed by one person without leaving the cab of the vehicle). - Speed Range

Forward speed: Minimum: 5 mph (8 kph); Maximum: 100 mph (160 kph) for Class I data (1” / 25 mm sampling interval). - Temperature

Operating ambient temperature range: 32° to 128° F (0-53°C); non-laser component operating temperature range: 0 to 140 F (-18-60°C). - Humidity

Operating humidity should not exceed 90 percent (noncondensing); non-operating humidity range shall not exceed 100 percent (noncondensing). - Moisture

Profiling system components impervious to moisture. Quality of measured profile degrades with excessive moisture (active rainfall, standing water or ponding on surface) - Dimensions

- CS8700 Lightweight Profiler: Click to see Polaris Ranger 570-EFI vehicle specifications.

- CS9100 Mid-Mount Profiler: Sensor modules: 10.5”L x 5.5”W x 3.75”H (cm: 26.7Lx14Wx9.5H)

- Control module: 12”Lx12”Wx5H” (cm: 30.5Lx30.5Wx12.7H).

- CS9200 Trailer Profiler: 10’Lx6.5’Wx3’H (cm: 152Lx20.3Wx61H).

- CS9300 Portable Profiler: 60”Lx8”Wx24”H (cm: 152Lx20.3Wx61H).

- CS9400 Simple Profiler: 24”Lx8”Wx24”H (cm: 61Lx20.3Wx61H)

- Weight

- CS8700 Lightweight Profiler: ~1100lbs (500kg); <10 PSI impact on pavement.

- CS9100 Mid-Mount Profiler: 30 lbs (13.6 kg) or less.

- CS9200 Trailer Profiler: 400-450lbs (180-205 kg); <10 PSI impact on pavement.

- CS9300 Portable Profiler: ~75 lbs (34 kg).

- CS9400 Simple Profiler: ~40 lbs (16 kg).

- Electrical Rating

- Input: 10-14 volts DC.

- Operating: 3 to 8 amps.

Cross-Slope

For advanced applications, SSI’s inertial profiling systems are scalable; more sensors can be added to support end user needs or agency requirements. Cross-slope can be reported using the laser readings and cancelling vehicle motion with IMU data.

- IMU Pitch and Roll Accuracy: 0.02 degrees

- IMU Heading Accuracy: 0.1 degree

- IMU Velocity Accuracy: 0.02 m/sec HRMS

- Satellite Signals: L1/L2

- Cold Start, Time to First Fix: <60 seconds

- Dynamic Range (Gyro, Accelerometer): 125˚/s, 8g

- Bias Instability (Gyro, Accelerometer): 0.8˚/h, 3.2µg

Optional Accessories

- GPS

Coordinates from GPS subsystem correlated with profiling system station (chainage) data, Google Earth overhead imagery and Trace View navigation program. Standard GPS at 5Hz. Medium option GPS at 10-20Hz with 2.3ft/0.7m accuracy; real time navigation supported. - Texture Measurement

Report MPD (ASTM E1845), ETD, RMS at highway speeds at a user specified interval. - Specialty Lasers

Line scan sensors available for improved testing on concrete and grinding pavements. Higher speed lasers available for texture measurement. - Survey Resolution GPS

Mobile surveying subsystem available with PPK corrected GPS data merged with profile data for high resolution topography mapping. Data outputs in typical survey format (e.g. PNEZD, LAS, etc.) for surface design in civil engineering applications and machine control applications. - Rut Depth

Several configurations available for measuring rut depth: 3 point (South Dakota method), 5 point (AASHTO PP 38), or full lane width transverse profile (CS9500) - Transverse Profile

Full lane width transverse profile across 14 feet (4.27 meters) using 6 ultra wide-beam 1280 point lasers. Developed pursuant to AASHTO provisional standards (PP067, PP068, PP069 and PP070). - Geometry

Road geometry measurements distilled from an optional tactical grade Inertial Measurement Unit (IMU). - Camera

Dashboard mounted digital camera for roadside images merged with profile data at user specified intervals. - Multi-System Integration

Support for profiling system integration with other sub-systems (imaging, asset inventory, surface distress, rut depth measurement, GPS/GIS, etc.) available. UDP or other compatible system interface support provided for integration of profiling system with other data collection and reporting systems. - Printer

Optional on-board custom thermal printer (4″ paper width; continuous feed; wider paper widths available). Windows compatible printer. AC power source for office use available.

Zero-Speed Inertial Profiler Upgrade

The Zero-Speed upgrade can be added to any SSI inertial profiler. The patent pending technology allows for collection speeds between 0-100 mph (0-161 kph) even through stoppages. The SSI method combines data with a high accuracy to still pass AASHTO r56 certifications through stoppages.

The Evolution of GPS Accuracy

SSI’s basic GPS option includes 5 Hz GPS receiver embedded within the profiling system electronics. The GPS readings are added to the profile data so that localized roughness and user events can be located by GPS. The GPS readings can also be used to view overhead areas of the surface in Google Earth or GPS Tagging.

Additional GPS receiver options are available from SSI which include network or satellite corrections to achieve 0.1-meter or RTK accuracy at up to 100 Hz.

With the use of an IMU, the GPS position can be “filled in” when sky-view and satellites are lost. This adds a major benefit for urban or mountain profiling and enhances the capabilities of a GPS-DMI, or INS-DMI.

Survey GPS

Combining the best characteristics of inertial profilers with the best of survey instrumentation, SSI offers a Survey Profiler capable of generating topography data as low as a 5mm x 5mm sampling interval. This system combines SSI profiling electronics and Post-Processed Kinetic (PPK) GPS corrections to create a 3D surface without the need for radio connection between the base station and vehicle.

The data may be exported in traditional survey formats, but the preferred format for this point density of data is LAS. The CS9500 Survey Profiler becomes a roving GPS unit with PPK corrections communicated via a static base station or a group of networked base stations.

The finished data can be imported into standard CAD programs for road design and machine control applications. For details on the mobile surveying systems, see the Offroad Survey Systems and CS9500 Full Lane Survey Profiler