CS9500 Full Lane Survey Profiler

Two-in-One System. Collect Data Faster and With More Accuracy.

At A Glance

Top Five Reasons Our Users Prefer the CS9500:

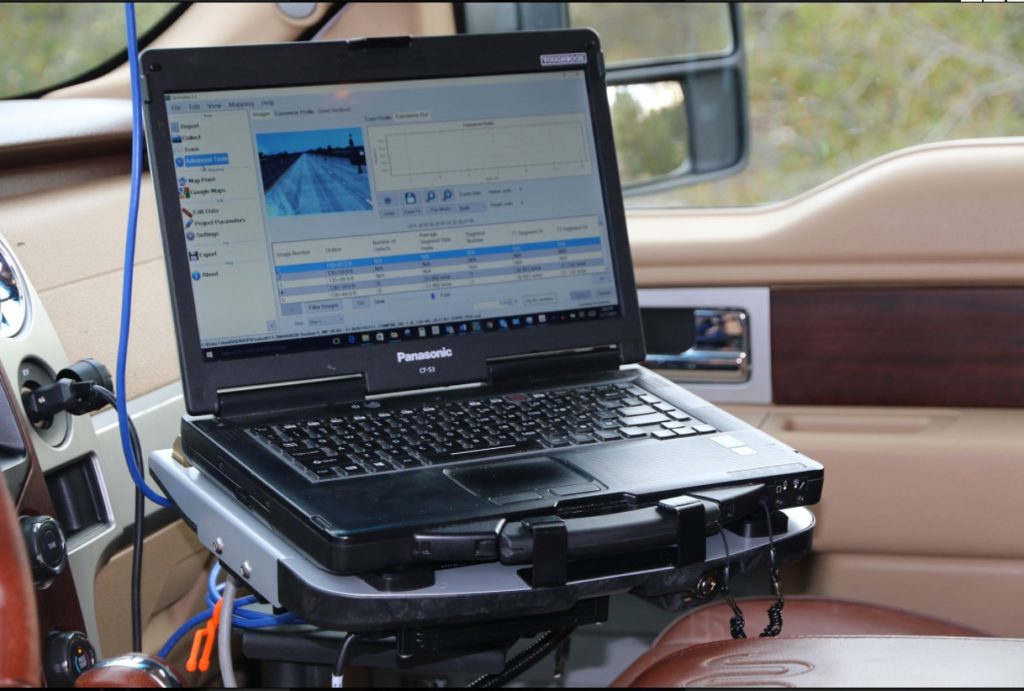

- Two-in-One system. Inertial Profiler for IRI and Survey Scanner. Save Money. Maintain less equipment. Instant IRI Reporting.

- Only One Pass Per Lane Needed. Save Time on Collections.

- Fixed Sampling Interval at Highway Speeds.

- Zero-Speed Profiler – Collect Down to a Stop.

- IRI Based 2D or true 3D Models.

The CS9500 system has these core features:

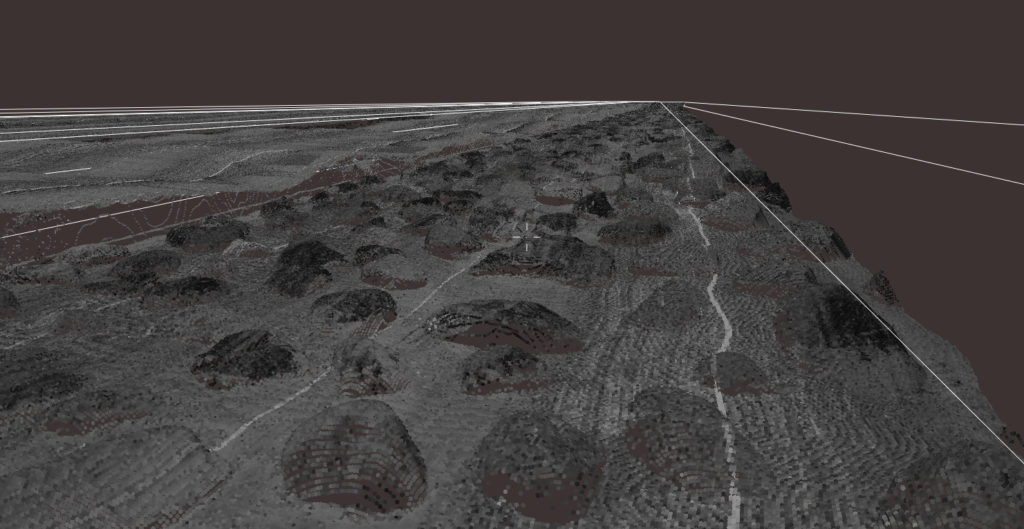

- Collect over 9 million points per mile.

- No filtering of laser data needed. Only collect the pavement surface.

- DOT certified inertial profiler (AASHTO R56-57, ASTM E950) integrated within system and simultaneously collects data

- Zero-Speed inertial profiler to collect profile data from 0-100mph

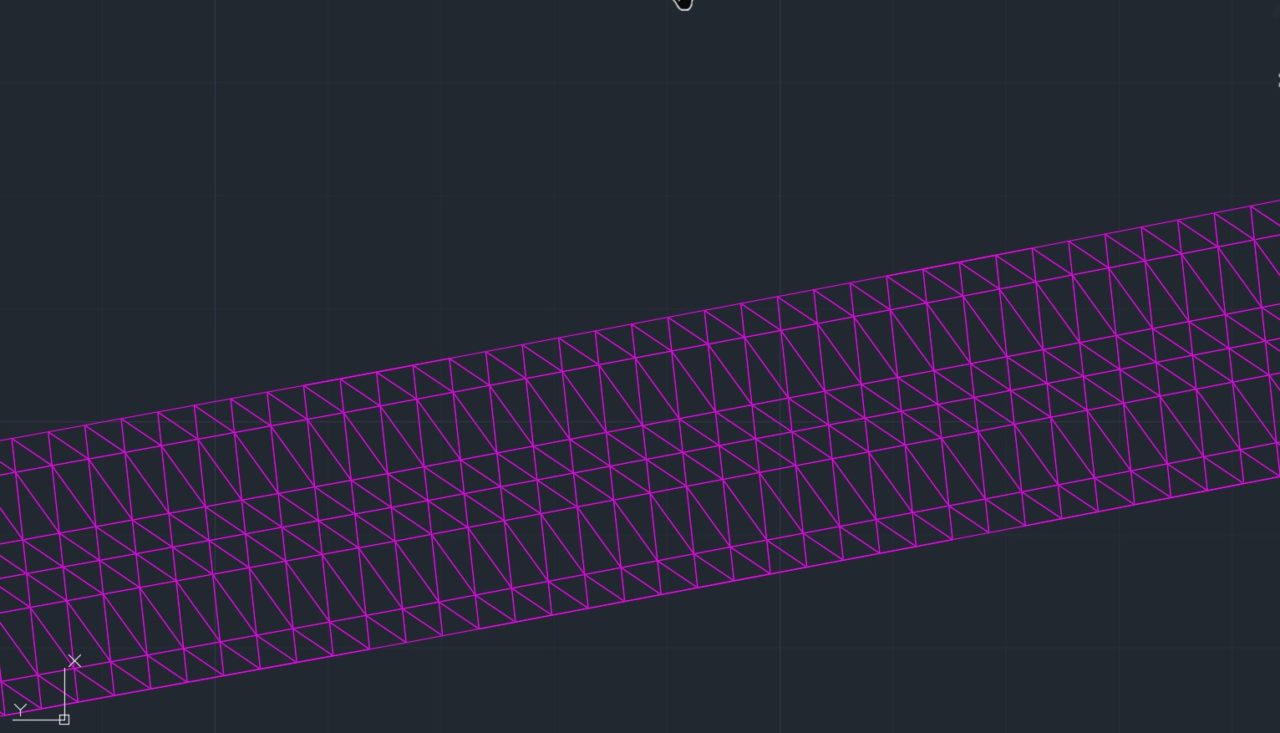

- Typical 2″x0.5″ point cloud at 55mph (50mmx12mm at 88 kph)

- SSI CAD program to merge control points into dataset for secondary correction

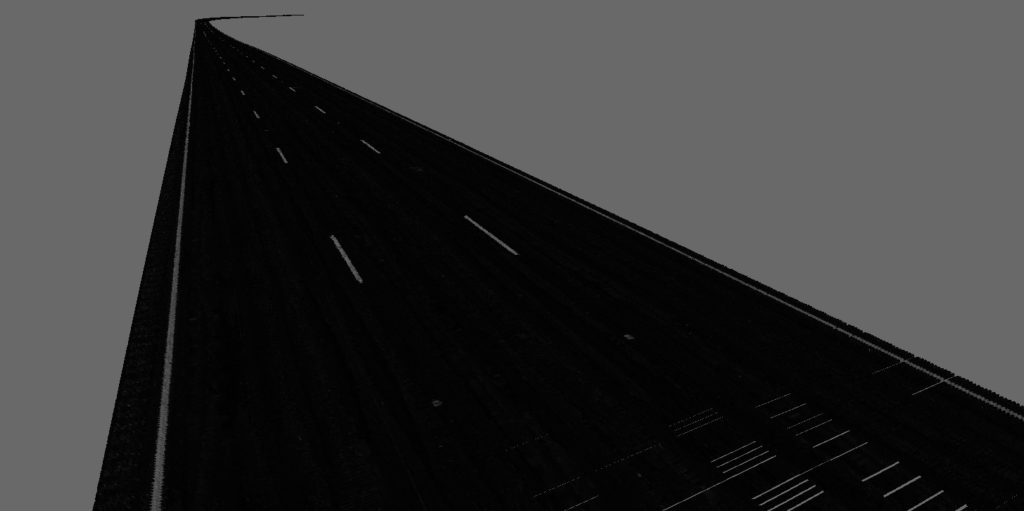

- Intensity displays lane lines and delineation

- Scalable: Start with dual track profile, add cross-slope, transverse & 3D Scanning

- Supports full lane width 3D scanning and rut measurement

- SSI software merges elevation correction points for precise 3D elevations

- Outputs data in common formats (e.g.) PNEZD, PLLHD, GPGGA, and LAS

- Reusable container for storing costly sensors off-vehicle

PPK corrections and accurate sensors allow for fast collections and even fast processing. The CS9500 only needs one pass per lane.

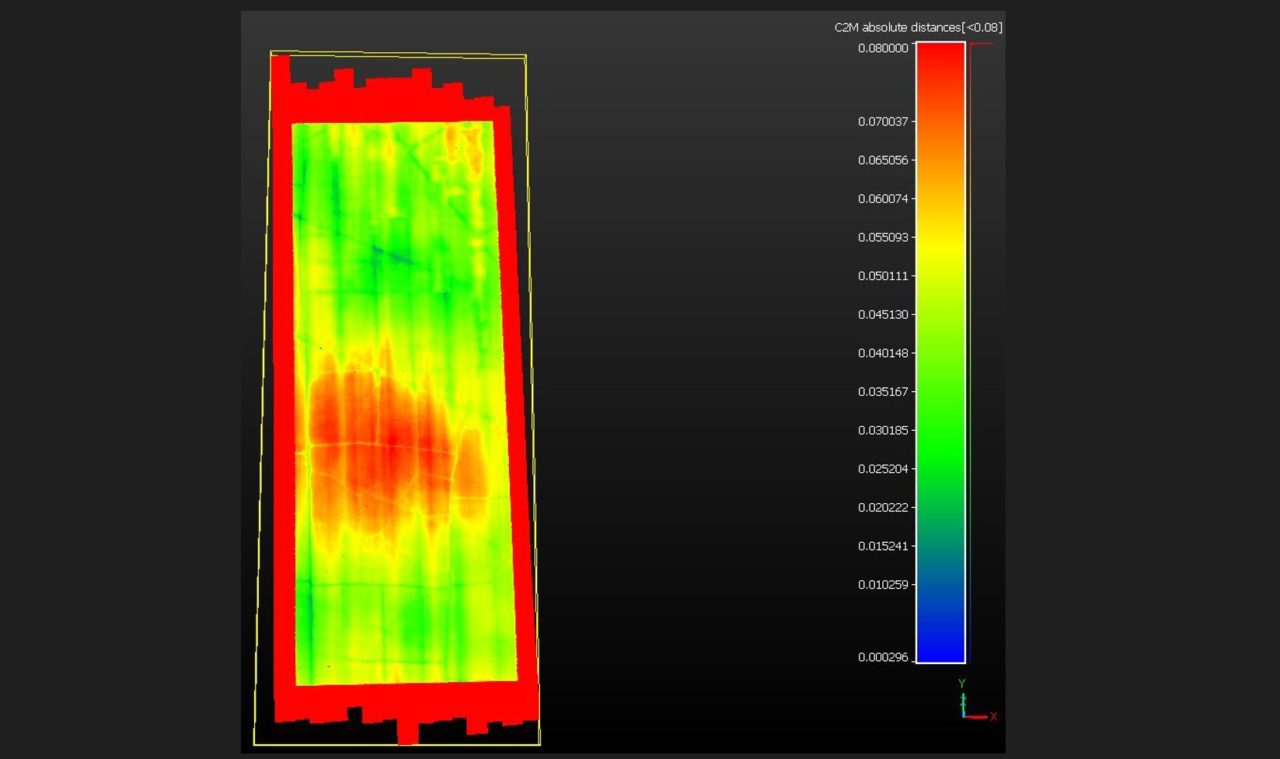

With correction points the scan data can be corrected to be within 6mm for 95% of the point cloud. Correction points are only needed every 2,000-4,000 feet. Correction points are not needed for 2D or 2D+ differential/relative machine control models.

All-In-One Design

The CS9500 Survey-Profile system is both a DOT certified inertial profiler and high resolution mobile surveying system. The CS9500 can simultaneously measure IRI (longitudinal profile), transverse profile and 2D/3D surface scans for land surveying and machine control applications. The survey side of CS9500 system has been end-user validated as more accurate than any commercial vehicle scanning system. This device does full 3D scanning and can be simultaneously (or separately) used for IRI testing and full lane transverse profiles (for rutting, lane edge change and more under AASHTO PP69-10 & 70-10). The surface survey data can be adjusted with a merge in of control points for very accurate 3D elevation content.

2D+ or 3D Capable

The CS9500 system can also be used for 2D scanning for pavement rehabilitation work that does not involve paving to absolute elevation. SSI’s software includes a Profile Design module for configuring slope and cut/fill parameters for a design output optimized for best IRI results. The data can be exported to machine control systems, including 2D or true 3D grade control systems.